Fair production in Portugal

Fair production in Portugal

Sustainable Production

Each step in the production process from A to Z has been made as fair, sustainable and transparent as possible.

This means:

- fair wages and working conditions in Portugal

- Production by small scale businesses within 100km radius

- Energy and water saving processes

- Lifespan increasing choices

- No plastic packaging

But the work is never finished and we are continually improving the process.

Sustainable Production

Each step in the production process from A to Z has been made as fair, sustainable and transparent as possible.

This means:

- fair wages and working conditions in Portugal

- Production by small scale businesses within 100km radius

- Energy and water saving processes

- Lifespan increasing choices

- No plastic packaging

But the work is never finished and we are continually improving the process.

“We don’t realise that clothes go halfway around the world in production, before they arrive in the shop”.

Around the world

Clothing production can clock up to 23,000 km. The different processes can take place in as many as four different countries on different continents.

Source: Oneworld.nl

Photo Fleur Hogenkamp

portugal <100KM

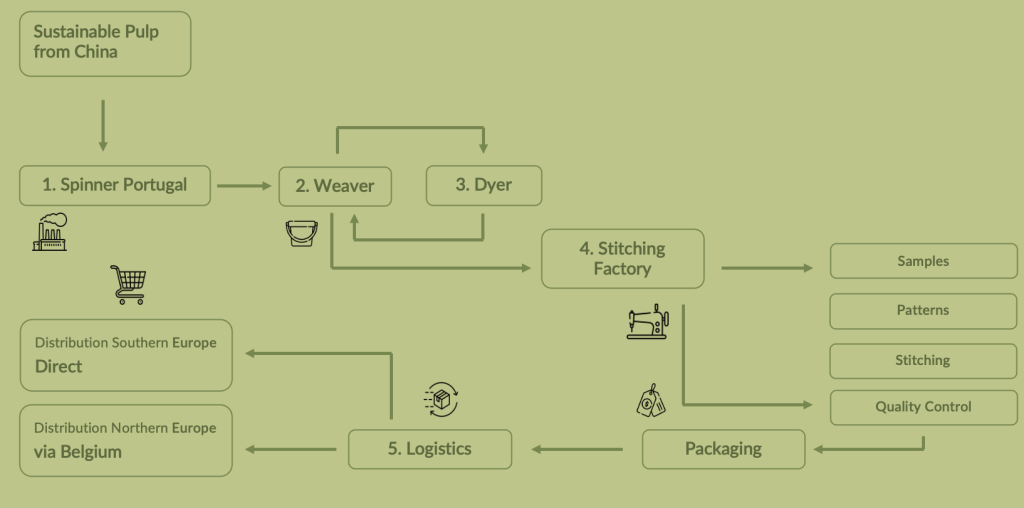

Bamboo Belgium’s production happens via five local partners. All partners are located within radius of only 100km.

Our production process

Our production process

Sustainable pulp

Until now only the bamboo pulp comes from bamboo fields in China.

Our partner in China is certified for sustainable cultivation and makes use of a ‘closed loop’ process.

This implies that:

- Bamboo pulp is cultivated with sodium in the water.

- Waste water is neutralised and recycled.

Within 5 years the goal is to build our own pulp factory in Portugal to process locally grown bamboo into pulp.

Sustainable pulp

Until now only the bamboo pulp comes from bamboo fields in China.

Our partner in China is certified for sustainable cultivation and makes use of a ‘closed loop’ process.

This implies that:

- Bamboo pulp is cultivated with sodium in the water.

- Waste water is neutralised and recycled.

Within 5 years the goal is to build our own pulp factory in Portugal to process locally grown bamboo into pulp.

Dry Spinning

Did you know that around 2,700 liters of water is needed to produce one T-Shirt?

That is about the same as 2.5 years of drinking water for one person.

This is the reason that Bamboo Belgium works together with our partner Vera, who use the dry spun technique, to implement large scale water savings in the production process.

In other words, we spin without using water.

Dry Spinning

Did you know that around 2,700 liters of water is needed to produce one T-Shirt?

That is about the same as 2.5 years of drinking water for one person.

This is the reason that Bamboo Belgium works together with our partner Vera, who use the dry spun technique, to implement large scale water savings in the production process.

In other words, we spin without using water.

bAwear Score

To measurably reduce the ecological footprint with sustainable bamboo clothing, we are working together with bAwear which allows us to make the impact of textiles transparent and accessible to all stakeholders in the supply chain. Based on the bAwear score, we easily and independently calculate, verify and report the sustainable impact of Bamboo Belgium clothing. This results in impressive figures as we drastically reduce Co2 emissions. We now produce a Bamboo Belgium t-shirt with only 27 litres of water compared to 2,700 litres for an unsustainable t-shirt. Even better: thanks to planting our first own bamboo fields in Belgium in 2023, we will produce Co2 neutral bamboo clothing. By doing so, we are not only giving Co2 back to the earth, but also land for more bamboo.

Weaving

First the spun yarn goes to our weaver to make the Jersey, Sweat or Satin fabric.

Next, the fabric goes to the dyer and from there back to the weaver, for a special finishing touch to prevent pilling.

Both the choice of a quality dye and the piling finish by the weaver, ensure a longer wear lifespan.

Our sustainable bamboo clothing lasts at least 2x longer as high quality clothing. You can easily wear a t-shirt for 5 years, using it once or twice per week.

Weaving

First the spun yarn goes to our weaver to make the Jersey, Sweat or Satin fabric.

Next, the fabric goes to the dyer and from there back to the weaver, for a special finishing touch to prevent pilling.

Both the choice of a quality dye and the piling finish by the weaver, ensure a longer wear lifespan.

Our sustainable bamboo clothing lasts at least 2x longer as high quality clothing. You can easily wear a t-shirt for 5 years, using it once or twice per week.

Ecological Dye

In order to prolong the quality and life of our bamboo clothing, we dye it as ecologically as possible.

The polluting fabric dyes which are widely used in the industry are not only environmentally polluting but also a chemicals worn on the skin day to day.

We don’t want to support this as our goal is to be good for people, animals and the environment.

Ecological Dye

In order to prolong the quality and life of our bamboo clothing, we dye it as ecologically as possible.

The polluting fabric dyes which are widely used in the industry are not only environmentally polluting but also a chemicals worn on the skin day to day.

We don’t want to support this as our goal is to be good for people, animals and the environment.

Artisanal Production

We consciously chose not to work with mass production, where profit maximization is key, but rather value the care and attention to each step of the process of artisanal production.

- We make samples, draw patterns and cut fabric by hand.

- The bamboo clothing is stitched together by a permanent stitching team.

- During the production process, ironing and packing our Quality Manager Leonor oversees quality controls to make sure that our bamboo clothing arrives to our clients in perfect condition.

Artisinal Production

We consciously chose not to work with mass production, where profit maximization is key, but rather value the care and attention to each step of the process of artisanal production.

- We make samples, draw patterns and cut fabric by hand.

- The bamboo clothing is stitched together by a permanent stitching team.

- During the production process, ironing and packing our Quality Manager Leonor oversees quality controls to make sure that our bamboo clothing arrives to our clients in perfect condition.

Logistics

Through our local production, within a 100km radius and also through efficient slow transport we are reducing our transport costs and our CO2 emissions.

Transportation and delivery takes longer with us than you might be used to from other suppliers but here, we are also choosing the most sustainable option.

Mostly we produce to order, which means we only have a small clothing stock. The distribution for Southern Europe goes directly from the factory. Distribution in Northern Europe runs via Belgium.

For transportation to the shops the bamboo clothing is packaged minimally and completely plastic free, in recycled tissue paper.

Logistics

Through our local production, within a 100km radius and also through efficient slow transport we are reducing our transport costs and our CO2 emissions.

Transportation and delivery takes longer with us than you might be used to from other suppliers but here, we are also choosing the most sustainable option.

Mostly we produce to order, which means we only have a small clothing stock. The distribution for Southern Europe goes directly from the factory. Distribution in Northern Europe runs via Belgium.

For transportation to the shops the bamboo clothing is packaged minimally and completely plastic free, in recycled tissue paper.

Bamboo News

© 2024 Bamboo Belgium | All rights reserved